CO₂, temperature and humidity sensor

Product description

The Pressac wireless CO₂ sensor is designed to measure and report levels of carbon dioxide, ambient temperature and relative humidity in an internal environment. During normal operation, the sensor is powered from ambient room light: in prolonged low-light environments the security of battery back-up ensures up to 10* years of continued maintenance-free operation. The sensor supports the open EnOcean standard (ISO/IEC 14543-3-10), facilitating seamless connection with building management systems.

Key features and benefits

- Energy harvesting – powered by ambient light from the surrounding environment

- On-board energy storage allows sensor to operate from stored solar power for several hours after darkness before switching to battery power

- Maintenance-free – for cost efficiency

- No wiring required – low cost of installation

- Fast installation time – minimal disruption for retro fits

- Optimal positioning – no wiring constraints

Available variants

| Frequency | Frequency Type | Part Number |

| 868MHz | EnOcean for Europe | 60_CO2_SLR_TMP_HUM_868 |

| 902MHz | EnOcean for USA/Canada | 60_CO2_SLR_TMP_HUM_902 |

| 928MHz | EnOcean for Japan | 60_CO2_SLR_TMP_HUM_928 |

Installation

We recommend the Pressac CO₂ sensor is installed in an environment where:

- The local CO₂ level is representative of the complete area being measured i.e. do not place the unit close to a frequently opened window or air conditioning unit.

- A source of either natural or artificial light is available during the hours when the building is occupied (due to the unit being solar-powered).

Note: We recommend you perform a manual calibration before the sensor is commissioned to ensure accurate CO₂ reporting.

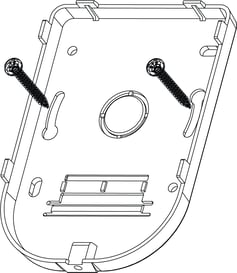

Installation of backplate

The Pressac CO₂ sensor is designed to be wall mounted. For ease of installation, it is supplied with a backplate that can be mounted on the wall prior to installation of the CO₂ sensor itself.

The backplate can be wall mounted either using the screws and raw plugs provided, or alternatively it can be mounted over an existing ‘pattress’ box using the appropriate machine screws (not provided).

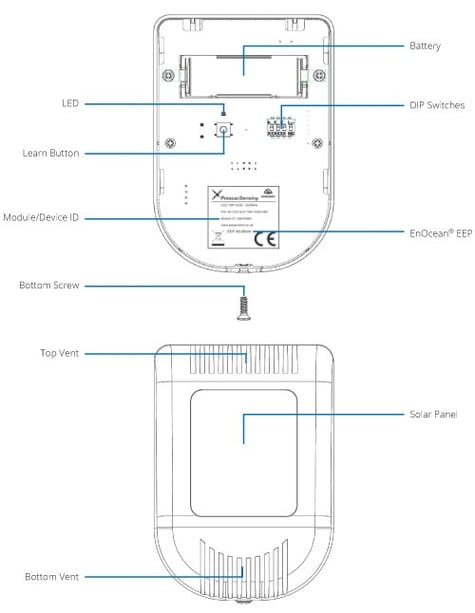

Installation of unit on backplate

Note: Before permanently attaching the sensor to the backplate, make sure that you have completed the setup and commissioning process as described in the product operation section.

The CO₂ sensor will latch onto the previously mounted backplate via the latches on the top of the unit.

Once latched, the securing screw at the bottom of the backplate can be tightened.

Commissioning

The Pressac sensing CO₂ sensor needs to be commissioned before use. There are four stages to the commissioning process.

1. Selection of sampling rate

As the unit is designed to harvest energy from ambient light, it may be favourable (where applicable) to reduce the unit’s sampling frequency in prolonged low-level light conditions. This can be set by configuring DIP switch 1 as below.

| Light Status | Energy Supply | Sampling Rate | DIP Switch 1 |

| Ambient light good | (Powered from solar) | Fixed (15 mins) | On |

| Ambient light poor | (Powered from stored energy) | Fixed (15 mins) | On |

| Ambient light poor | (Powered from battery) | Fixed (15 mins) | On |

| Ambient light good | (Powered by solar) | Dynamic (5 mins) | Off |

| Ambient light poor | (Powered from stored energy) | Dynamic (5 mins) | Off |

| Ambient light poor | (Powered from battery) | Dynamic (15 mins) | Off |

2. Calibration

The CO₂ sensor has been factory calibrated prior to supply. Like all CO₂ sensors, it does need to update its calibration status periodically. In normal environments, background CO₂ levels are typically 500ppm.

Auto calibration ON/OFF

Auto calibration ON calibrates the reported background level of CO₂ against the lowest measured values of CO₂ taken over an eight-day period. Auto calibration is the preferred operating mode of the CO₂ sensor. However, to maintain accuracy, there must be periods of low room occupancy (only background CO₂ present) during the eight-day period.

Manual calibration

When first installing, and when auto calibration is not used, it is essential to recalibrate the unit’s background CO₂ level of 500ppm.

To recalibrate the default level of 500ppm, set DIP Switch 3 (manual calibration) and DIP switch 4 (battery backup) to ON and press the learn button for five seconds. The unit’s LED will flash once per second for approximately four minutes.

During this time, take the unit to an unoccupied environment (the ambient CO₂ level here should be approximately 500ppm).

After the four-minute period, the unit’s LED will flash quickly for a further two minutes while the recalibration process takes place.

Once the LED has stopped flashing, the unit’s base CO₂ level has been reset to 500PPM. Return DIP Switch 3 to the off position. DIP switch 4 can be left in the ON position if the battery backup function is required.

Moving DIP switch 3 back to the OFF position during the procedure will abort the calibration process.

| Operating Mode (Calibration) | DIP Switch 2 | Dip Switch 3 | Learn Button |

| Sensor auto-calibrates every eight days | ON | OFF | N/A |

| Sensor uses factory calibration level (500ppm) | OFF | OFF | N/A |

| Sensor uses recalibrated background level on completion | OFF | ON | Pressed |

3. Connection of battery

| Battery | Unit Status | Dip Switch 4 |

| Not connected | Solar powered only | OFF |

| Connected | Solar + battery powered | ON |

The unit is pre-installed with a non-rechargeable 3.6v Lithium A type battery. To enable commissioning and provide battery back-up operation in continuously low-level light conditions, the battery must be connected by switching DIP Switch 4 on.

4. Commissioning

There are two ways in which the unit can be commissioned.

Automatic registration

To commission the unit, depress and release the “Learn” button. The LED will blink once. The unit now transmits a learn telegram.

Manual registration

Alternatively, the unit can be commissioned onto your EnOcean network manually. To do this, you will need the unique EnOcean ID of the Pressac CO₂ sensor and also its EnOcean Equipment Profile (EEP). The EnOcean ID and the EEP are printed on the product label.

EnOcean Equipment Profile

The product uses an EnOcean module for transmitting the data wirelessly. It supports the following EEPs (EnOcean Equipment Profiles): A5-09-04.

Technical specifications

| Measurement range | CO₂ 0-2550 PPM Temperature 0ºC to +51ºC Humidity 0-100% RH |

| Accuracy | CO₂ +/- 125 PPM Temperature +/- 0.5ºC Humidity +/- 5% for RH |

| Sampling rate | Can be fixed to 15 minutes or can dynamically adjust between five and 15 minutes, depending on power source and light conditions |

| Repeater | No |

| Telegram | 4BS |

| Environment | IP2X |

| Battery* back-up | 3.6v A size non-rechargeable Lithium |

| Enclosure material | ABS |

| Calibration | Manual or auto recalibrates every 8 days |

| Solar | Amorphous Silicon Solar Cells |

| Operating temperature & humidity range | -5ºC to +60ºC |

| Storage temperature & humidity range | -20ºC to +55ºC |

| Sensor response time | Telegram transmission is within two seconds of measurement |

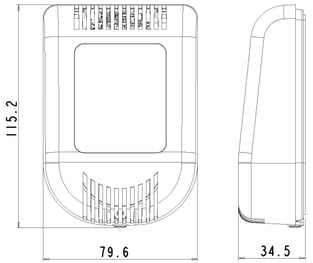

| Dimensions | 115mm x 80mm x 35mm approx. |

| EEP | A5-09-04 |

Note: *Typical life expectancy of the battery is dependent on use-case.

FAQ and troubleshooting

What is the range of the CO₂, temperature and humidity sensor?

This sensor communicates via the EnOcean protocol and has a maximum range of 30 metres. Please refer to the EnOcean wireless guidelines for further details.

How is the CO₂, temperature and humidity sensor powered?

Energy is harvested via the solar panel to power the device. Excess harvested energy is stored in the super capacitor, acting as a buffer during inconsistent light conditions. In addition to the super capacitor, the product features a back-up battery – ensuring uninterrupted operation during low lux levels.

How long does the CO₂, temperature and humidity sensor take to start operating for the first time?

As soon as the back-up battery is switched on the product is operational. The time taken to harvest energy will depend on the lighting conditions and the time taken to send the first telegram will depend upon the device’s settings. If the product is set to fixed sampling it will take 15 minutes, or five minutes when powered by energy harvesting. Pressing the learn button will send the learn telegram instantly, followed by a current data telegram within 10 seconds.

What is the minimum lux level for the CO₂, temperature and humidity sensor?

For energy-harvesting operation, an ambient level of above ≈500 Lux is advised.

What are the specifications of CO₂, temperature and humidity sensor’s battery?

3.6V A Size non-rechargeable Lithium.

Are replacement backup batteries for the CO₂, temperature and humidity sensor available?

Yes, the battery must be replaced with another 3.6V Size A non-rechargeable Lithium these are available from most component distribution warehouses.

How long can the back-up battery power the CO₂, temperature and humidity sensor for?

The battery should power the sensor for 10 years. However, this is dependent on operation.

Can the CO₂, temperature and humidity sensor operate without the back-up battery inserted?

Although the CO₂, temperature and humidity sensor can function without the back-up battery inserted or switched on, it is advised that it be inserted and switched on. This ensures optimum functionality in periodically low lux environments and important background tasks such as Automatic Background Calibration can be completed.

What if the CO₂, temperature and humidity sensor battery is removed and then re-inserted?

Removing the battery is not advised. However, if removed and re-inserted, you must perform a manual calibration to ensure sensor accuracy.

What is the super capacitor?

The super capacitor is a built-in power storage component charged via excess energy from the energy-harvesting solar panel.

How long can the super capacitor power the product for?

If fully charged, the super capacitor will provide approximately five hours of normal operation.

What level of Ingress Protection (IP Rating) does the product have?

The product has an IP rating of IP2X.

Can the CO₂, temperature and humidity sensor be painted?

The product’s warranty will be void if the product is painted.

How accurate is the CO₂, temperature and humidity sensor?

The CO₂ sensor’s accuracy is ± 125 Parts Per Million (PPM).